A deep dive into the lost art of loopwheeling

We’re big fans of loopwheel cotton here at Rivet & Hide. From Iron Heart’s Ultra Heavyweight Hoodies to Merz b. Schwanen’s now-iconic 215 “The Bear” tee, to The Real McCoy’s extensive Wakayama knit programme. We’ve seen first-hand how good it gets, and we’ve always been eager to bring it to you.

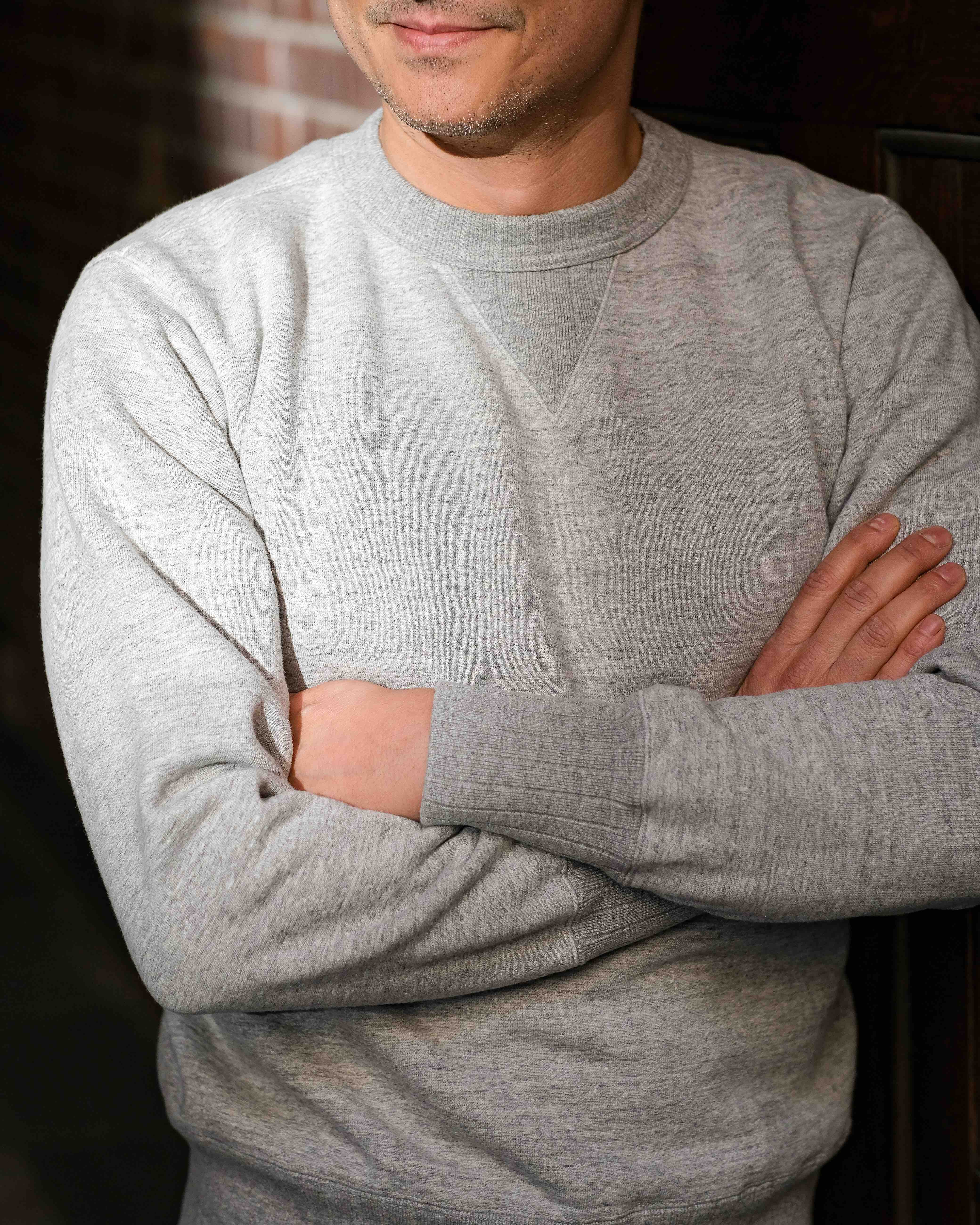

Loopwheel cotton can be a very expressive fabric with tons of natural texture and heft. These features make it the perfect choice for tees, sweaters, henleys, and sweatpants.

Loopwheeled cotton is somehow both tough-as-nails and soft as a warm hug. But for many, it’s still a bit of a mystery. So allow us to demystify the popularity of loopwheel t shirts a little.

What is Loopwheeling?

Loopwheeling is an old-school knitting method. Loopwheeling uses vintage circular knitting machines - often suspended vertically - to create seamless tubes of jersey fabric. These machines operate at extremely low speeds with minimal tension, producing cotton that’s soft, textured, and incredibly durable.

Where modern machines race ahead with speed and uniformity, loopwheelers embrace slowness and subtle imperfection. That’s exactly where their magic of loopwheeling lies.

The fabric advances with little more than the pull of gravity. As a result, it’s not only soft and airy, but also full of body and structure. Loopwheeling creates a superior fabric to both hand and eye. The output is a voluminous, slubby and irregular texture that recalls the charm of hand-knit garments.

Loopwheel machines are becoming increasingly rare. These relics were largely phased out in the 1950s in favour of faster, mass-production machines. The few that remain are entrusted to a small number of factories in Japan and Germany. Because these machines require expert care and constant attention to keep running.

How do Loopwheeler Machines Work?

In a word? Slowly.

Loopwheeling is a glacial knitting process. A loopwheel machine knits a single row of fabric at a time, producing as little as one metre of fabric per hour. For context, modern machines—like Sinker Needle models—can produce up to ten times that amount.

This slow pace is largely due to the fact that the loopwheeling process is gravity-fed. Rather than relying on mechanical pullers, loopwheelers use gravity to move the fabric downward. The major upside? This low-tension process gives loopwheeled fabric its signature loft, softness, and character.

Loopwheelers knit fabric in a continuous tube structure. This circular knitting method—often called “tube-knitting”—means no side seams on garments like tees and sweatshirts. That said, designers sometimes cut loopwheeled fabric after knitting for a different silhouette - which means some pieces do end up with side seams.

Loopwheel machines can often be slow and finicky. Each one is typically set up for a single garment size: one for smalls, another for larges, and so on. Each machine requires near-constant maintenance, often from a technician who knows its quirks inside and out.

Where is Loopwheeled Fabric Made?

The last operational loopwheelers are found mainly in Japan’s Wakayama Prefecture. In this region, you’ll find traditional tsuri-ami-ki machines are still in use. It’s estimated that fewer than 200 Japanese loopwheelers remain, some of which are nearly a century old.

The fabrics they produce are among the most textured and durable we’ve ever handled. Keeping these machines running is a labour of love. That’s why loopwheel machines entrusted to a small community of engineers and technicians still fluent in the old ways of these analogue relics.

Product Spotlight: The Merz b. Schwanen Loopwheeled 215 "The Bear" Tee

Loopwheeling has also seen a revival in Southern Germany, thanks to the family-owned Merz b. Schwanen. Originally founded in 1911 by Balthazar Merz, the company was revived in 2011 by Peter and Gitta Plotnicki.

The pair discovered a room full of vintage circular knitting machines in the Swabian Alps. Dating from the 1920s to the ’60s, these machines now power a renewed production of authentic, tube-knit loopwheeled garments.

This revival includes the now-iconic Merz b Schwanen loopwheeled 215 “The Bear” tee. Worn by Jeremy Allen White, this tee is known for its structure, durability, and unmatched vintage-like hand.

What’s So Special About Loopwheeled Fabrics?

Like we said, the entire loopwheeling process is almost completely tensionless. The fabric progresses with little more than the pull of gravity — no mechanical tension is used to move it along.

Every loopwheeled garment is unique

That slow, deliberate pace is exactly what makes loopwheeled cotton so special. The extended hang time allows more air into the yarns. Ultimately, this process gives the finished fabric a uniquely plush and breathable structure. It has a “dry” hand-feel and a gentle, natural stretch that wears beautifully over time.

Loopwheeled fabric also has excellent body; it holds its shape exceptionally well. It doesn’t warp, stretch out, or lose its character, even after repeated washing.

Loopwheeling creates unrivalled textures

Thanks to slight inconsistencies in tension and feed, loopwheeled garments often develop a slubby, irregular texture. They behave almost like hand-knit fabric. Much like our raw selvedge denim, each piece feels uniquely organic. These traditional processes create a tactile depth that modern mass-market machinery simply can’t replicate.

Loopwheel cotton garments are built to last

But the benefits of loopwheel sweatshirts and tees aren’t just aesthetic. The density of a loopwheel knit, with its natural softness and elasticity, gives garments lasting durability. Cotton yarn treated in this way will last longer, age better, and stay comfortable for years. Some of the loopwheeled tees in our own rotations are over a decade old - and still going strong.

Why you should invest in loopwheeled cotton

Ultimately, loopwheeled garments are for people who value how things are made — not just what they’re made of. Loopwheeled cotton is slower, rarer, and costlier to produce. But the result is a fabric that’s more comfortable, durable, and beautiful than anything a modern machine can make. If you love denim for its texture and fade, loopwheel cotton offers the same kind of depth in knitwear.

Explore our collection of loopwheel tshirts.

Or wrap yourself in a cosy loopwheel sweatshirt.